NdFeB Magnet Solutions

NdFeB magnets, also known as NdFeB magnets or neo magnets, are the third generation rare earth magnets independently developed by General Motors and Sumitomo Special Metals in the early 1980s. According to the manufacturing process, it can be divided into sintered NdFeB, bonded NdFeB, and hot-pressed NdFeB. Sintered neodymium magnets have the highest magnetic energy product of all types of permanent magnets.

UPSUN Magnets is committed to producing high-quality NdFeB magnets according to customer requirements. If you need us to provide you with customized services, then you can contact us directly by sending an email!

Most Powerful Permanent Magnets - Neodymium Magnets

NdFeB magnet (also known as Neo, NdFeB, or NIB magnet) is a permanent magnet material based on the Nd-Fe-B tetragonal structure. Sintered NdFeB magnets contain three basic elements of neodymium, iron, and boron, which are manufactured by powder metallurgy process.

Neodymium magnet is a new type of magnetic material with excellent magnetic properties and competitive cost. Sintered NdFeB magnets are widely used in DC motors, servo motors, stepping motors, voice coil motors (VCM), wind turbines, etc.

UPSUN Has been a leading supplier of high-quality sintered NdFeB magnets. We offer the most competitive prices in the industry along with in-house quality control and on-time delivery services.

NdFeB Magnets for Sale Online

Irregular Magnet

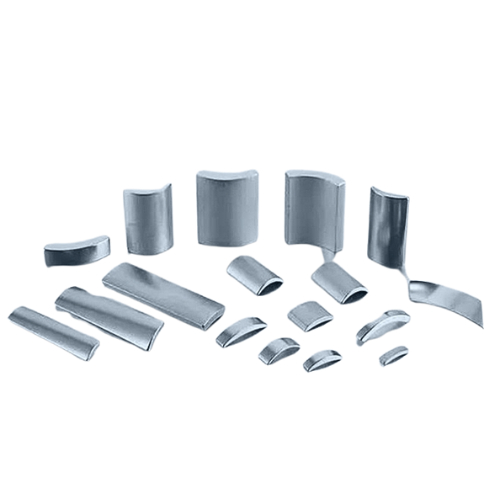

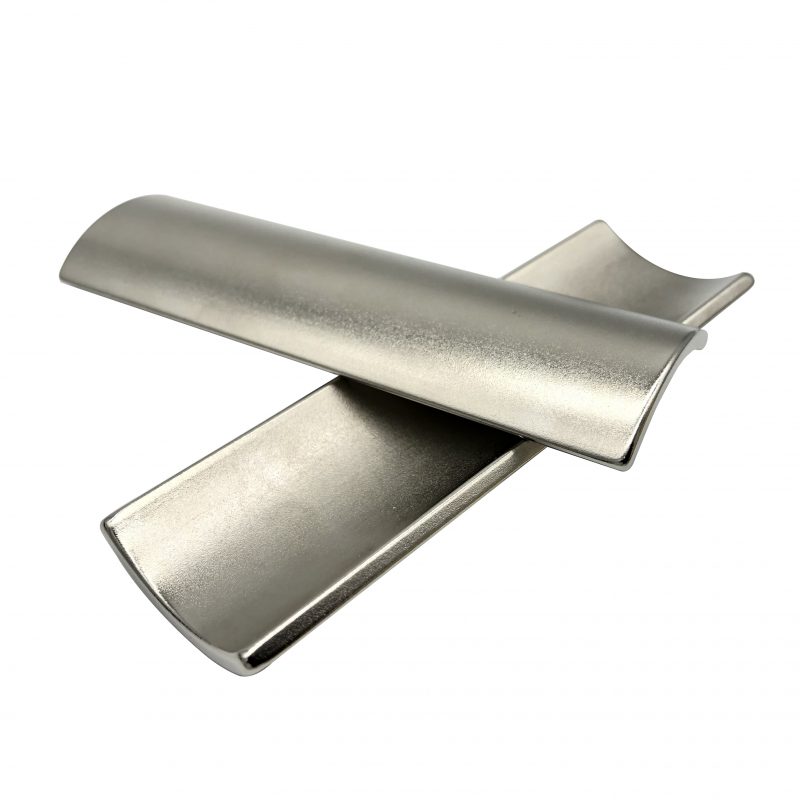

Arc Magnet

Block Magnet

Disc Magnet

Loaf Magnet

Ring Magnet

Customized NdFeB Magnet Services

As a top Chinese magnet manufacturer, we are fully capable of customizing various types of NdFeB magnets for your project, ensuring that the products we provide meet the needs of your project.

- Steady premium quality.

- Reliable & rapid delivery.

- Professional reports provided.

- Rich choice of magnetic material.

- EXW, FCA, CPT, CIP, DAT, DAP, DDP, FOB, CFR, CIF available.

- Customized for shapes, surface treaments, magnetization directions, etc.

Custom NdFeB Magnet Coating

Custom NdFeB Magnet Shape

Grades of Neodymium Magnets

| Grade | Remanence(BR) | Coercivity(Hcb) | Instrinsic Coercivity(Hcj) | Max Energy Product | Max Working temperature | ||||

| K Gauss | mT | K Oe | KA/m | K Oe | KA/m | MGOe | Kj/m³ | ℃ | |

| ND-30 | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥12.00 | ≥955 | 28~31 | 233~247 | <80℃ |

| ND-33 | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥12.00 | ≥955 | 31~34 | 247~271 | <80℃ |

| ND-35 | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥12.00 | ≥955 | 33~36 | 263~287 | <80℃ |

| ND-38 | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥12.00 | ≥955 | 36~39 | 287~310 | <80℃ |

| ND-40 | 12.50-12.80 | 1250-1280 | ≥11.40 | ≥907 | ≥12.00 | ≥955 | 38~41 | 302~326 | <80℃ |

| ND-42 | 12.80-13.20 | 1280-1320 | ≥11.50 | ≥915 | ≥12.00 | ≥955 | 40~43 | 318~340 | <80℃ |

| ND-45 | 13.20-13.80 | 1320-1380 | ≥11.60 | ≥876 | ≥12.00 | ≥955 | 43~46 | 342~366 | <80℃ |

| ND-48 | 13.80-14.20 | 1380-1420 | ≥11.60 | ≥836 | ≥12.00 | ≥955 | 46~49 | 366~390 | <80℃ |

| ND-50 | 14.00-14.50 | 1400-1450 | ≥10.00 | ≥796 | ≥11.00 | ≥876 | 48~51 | 382~406 | <80℃ |

| ND-52 | 14.30-14.80 | 1430-1480 | ≥10.00 | ≥796 | ≥11.00 | ≥876 | 50~53 | 398~422 | <80℃ |

| ND-30M | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥14.00 | ≥1114 | 28~31 | 233~247 | <100℃ |

| ND-33M | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥14.00 | ≥1114 | 31~34 | 247~271 | <100℃ |

| ND-35M | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥14.00 | ≥1114 | 33~36 | 263~287 | <100℃ |

| ND-38M | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥14.00 | ≥1114 | 36~39 | 287~310 | <100℃ |

| ND-40M | 12.50-12.80 | 1250-1280 | ≥11.60 | ≥923 | ≥14.00 | ≥1114 | 38~41 | 302~326 | <100℃ |

| ND-42M | 12.80-13.20 | 1280-1320 | ≥12.00 | ≥955 | ≥14.00 | ≥1114 | 40~43 | 318~340 | <100℃ |

| ND-45M | 13.20-13.80 | 1320-1380 | ≥12.50 | ≥955 | ≥14.00 | ≥1114 | 43~46 | 342~366 | <100℃ |

| ND-48M | 13.80-14.20 | 1380-1420 | ≥12.90 | ≥1027 | ≥14.00 | ≥1114 | 46~49 | 366~390 | <100℃ |

| ND-50M | 14.00-14.50 | 1400-1450 | ≥13.00 | ≥1027 | ≥14.00 | ≥1114 | 48~51 | 382~406 | <100℃ |

| ND-30H | 10.80-11.30 | 1080-1130 | ≥10.00 | ≥796 | ≥17.00 | ≥1353 | 28~31 | 233~247 | <120℃ |

| ND-33H | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥17.00 | ≥1353 | 31~34 | 247~271 | <120℃ |

| ND-35H | 11.70-12.20 | 1170-1220 | ≥10.90 | ≥868 | ≥17.00 | ≥1353 | 33~36 | 263~287 | <120℃ |

| ND-38H | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥17.00 | ≥1353 | 36~39 | 287~310 | <120℃ |

| ND-40H | 12.50-12.80 | 1250-1280 | ≥11.60 | ≥923 | ≥17.00 | ≥1353 | 38~41 | 302~326 | <120℃ |

| ND-42H | 12.80-13.20 | 1280-1320 | ≥12.00 | ≥923 | ≥17.00 | ≥1353 | 40~43 | 318~340 | <120℃ |

| ND-45H | 13.00-13.60 | 1300-1360 | ≥12.10 | ≥963 | ≥17.00 | ≥1353 | 43~46 | 342~366 | <120℃ |

| ND-48H | 13.70-14.30 | 1370-1430 | ≥12.50 | ≥995 | ≥17.00 | ≥1353 | 46~49 | 366~390 | <120℃ |

| ND-30SH | 10.80-11.30 | 1080-1130 | ≥10.10 | ≥804 | ≥20.00 | ≥1592 | 28~31 | 233~247 | <150℃ |

| ND-33SH | 11.30-11.70 | 1130-1170 | ≥10.60 | ≥844 | ≥20.00 | ≥1592 | 31~34 | 247~271 | <150℃ |

| ND-35SH | 11.70-12.20 | 1170-1220 | ≥11.00 | ≥876 | ≥20.00 | ≥1592 | 33~36 | 263~287 | <150℃ |

| ND-38SH | 12.20-12.50 | 1220-1250 | ≥11.40 | ≥907 | ≥20.00 | ≥1592 | 36~39 | 287~310 | <150℃ |

| ND-40SH | 12.50-12.80 | 1250-1280 | ≥11.80 | ≥939 | ≥20.00 | ≥1592 | 38~41 | 302~326 | <150℃ |

| ND-42SH | 12.80-13.20 | 1280-1320 | ≥12.40 | ≥987 | ≥20.00 | ≥1592 | 40~43 | 318~340 | <150℃ |

| ND-45SH | 13.20-13.80 | 1320-1380 | ≥12.60 | ≥1003 | ≥20.00 | ≥1592 | 43~46 | 342~366 | <180℃ |

| ND-28UH | 10.20-10.80 | 1020-1080 | ≥9.60 | ≥764 | ≥25.00 | ≥1990 | 26~29 | 207~231 | <180℃ |

| ND-30UH | 10.80-11.30 | 1080-1130 | ≥10.20 | ≥812 | ≥25.00 | ≥1990 | 28~31 | 233~247 | <180℃ |

| ND-33UH | 11.30-11.70 | 1130-1170 | ≥10.70 | ≥852 | ≥25.00 | ≥1990 | 31~34 | 247~271 | <180℃ |

| ND-35UH | 11.80-12.20 | 1180-1220 | ≥10.80 | ≥860 | ≥25.00 | ≥1990 | 33~36 | 263~287 | <180℃ |

| ND-38UH | 12.20-12.50 | 1220-1250 | ≥11.00 | ≥876 | ≥25.00 | ≥1990 | 36~39 | 287~310 | <180℃ |

| ND-40UH | 12.50-12.80 | 1250-1280 | ≥11.30 | ≥899 | ≥25.00 | ≥1990 | 38~41 | 302~326 | <200℃ |

| ND-28EH | 10.40-10.90 | 1040-1090 | ≥9.80 | ≥780 | ≥30.00 | ≥2388 | 26~29 | 207~231 | <200℃ |

| ND-30EH | 10.80-11.30 | 1080-1130 | ≥10.20 | ≥812 | ≥30.00 | ≥2388 | 28~31 | 233~247 | <200℃ |

| ND-33EH | 11.30-11.70 | 1130-1170 | ≥10.50 | ≥836 | ≥30.00 | ≥2388 | 31~34 | 247~271 | <200℃ |

| ND-35EH | 11.70-12.20 | 1170-1220 | ≥11.00 | ≥876 | ≥30.00 | ≥2388 | 33~36 | 263~287 | <200℃ |

| ND-38EH | 12.20-12.50 | 1220-1250 | ≥11.30 | ≥899 | ≥30.00 | ≥2388 | 36~39 | 287~310 | <200℃ |

Coating of Neodymium Magnets

| Coating | Thickness (μm) | SST (hr) | PCT (hr) | Tw (ºC) |

| Zn (Zinc) | 45061 | >24 | - | ≤160 |

| C-Zn (Colored Zinc) | 45061 | >48 | - | ≤160 |

| Electroless Nickel | 45229 | >96 | >72 | ≤230 |

| NiCuNi (Nickel Copper Nickel) | 45219 | >48 | >48 | ≤230 |

| NiCu + Black Nickel | 45219 | >48 | >72 | ≤230 |

| NiCuNi + Tin | 45224 | >48 | >48 | ≤160 |

| NiCuNi + Gold | 45224 | >48 | >48 | ≤230 |

| NiCuNi + Silver | 45224 | >48 | >48 | ≤160 |

| Epoxy | 45229 | >72 | >48 | ≤160 |

| Teflon | 45219 | >48 | - | ≤230 |

| Everlube | 45219 | >96 | >72 | ≤230 |

| Parylene | 0.2-5 | >96 | - | ≤230 |

Physical Properties of Neodymium Magnets

| Physical Properties | |

| Temp Coeff of Br | -0.09-0.11%/℃ |

| Density | 7.45~7.7g/cm3 |

| Vickers Hardness | 600Hv |

| Tensile Strength | 8.0kg/mm2 |

| Specific Heat | 0.12KCAL/(kg,℃) |

| Youngs Ratio | 1.6x1011N/m2 |

| Poissons Ratio | 0.24 |

| Curie Temperature | 310-340℃ |

| Temp Coeff of Hc | -0.48-0.63%/℃ |

| Electrical Resistivity | 114 μ Ω cm |

| Flexural Strength | 25kg/mm |

| Hardness | 0.64N/m2 |

| Compressibility | 9.8*10-12 m2/N |

| Coeff of Thermal Expansion | 4*10-6 /℃ |

| Thermal Conductivity | 7.7kcal/(m.h.℃) |

| Relative Recoil Permeability | 1.05 |

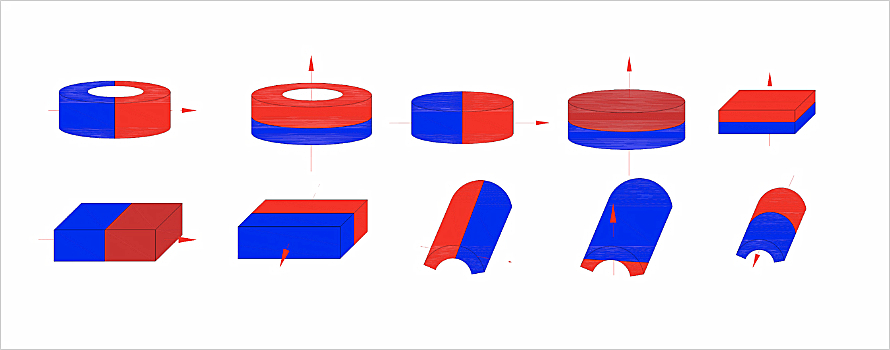

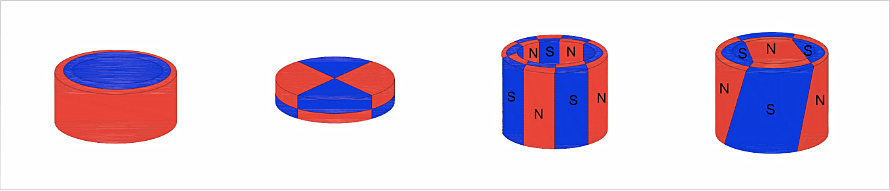

Neodymium Magnet Magnetization Direction

The direction is irreversible once it is oriented. The magnetized directions have the strongest magnetism, but the rest is very poor and weak. Hence, it should be taken into consideration bfore we start a product design or production

Single-pole Magnetization:

Magnets with a conventional magnetization pattern have a single, equal strength pole on each opposite face.

Multiple-pole Magnetization:

Magnets with a two-pole or multi-pole magnetization pattern have two or more poles on one face of the magnet.

The Manufacturing Process of Neodymium Magnets

Our ndfeb magnets are mainly used in the following fields: Motor industry, household appliances, sports equipment, medical equipment, transport, electronic equipment, audio visual. As a leading manufacturer and supplier of neodymium magnets in China. We produce high quality and affordable priced permanent rare earth sintered neodymium magnets and can help you select the right magnet for your application, just click to email.

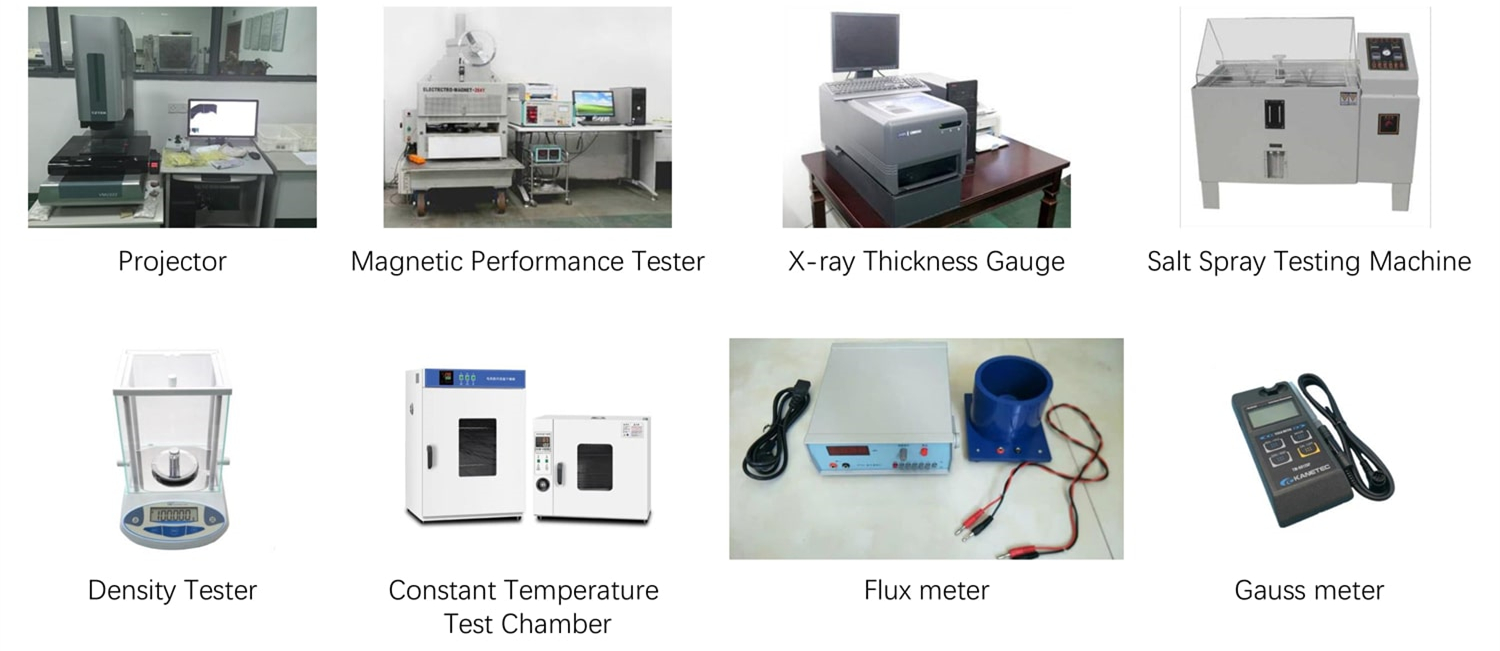

Quality Inspection

When it comes to accuracy, efficiency and cost competitiveness, manual inspection alone can no longer keep up. Therefore, we invested in automatic inspection machines that can quickly and accurately measure multiple dimensions, appearance, and reject substandard parts with very high productivity.

What Are the Main Uses of Neodymium Magnets?

Our NdFeB magnets are mainly used in the following fields: Motor industry, household appliances, sports equipment, medical equipment, transport, electronic equipment, and audio equipment.

As a leading manufacturer and supplier of NdFeB magnets in China. We produce high quality and affordable priced permanent rare earth sintered neodymium magnets and can help you select the right magnet for your application, just click to email.